Our Products

PV Mounting Bracket Roll Forming Machine

Trapezoidal Panel Roll Forming Machine

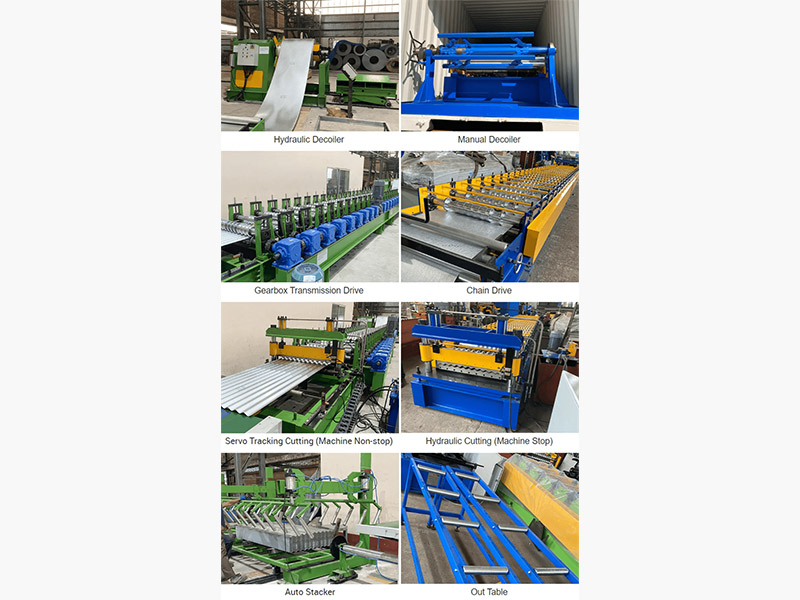

Different Trapezoidal panel roll forming machine can produce different shapes of steel trapezoidal sheets according to the client’s profile drawings and requirements. The steel trapezoidal sheets are new building materials with various thickness and colors. The finished products are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers etc.

Process Flow: Uncoiler — feeding— roll forming— cutting — output

Corrugated Panel Roll Forming Machine

Our PV Corrugated Panel Roll Forming Machine is a revolutionary equipment that produces sinusoidal wave shape panels using FULL HARD Galvanized steel with a yield strength of up to 550Mpa even 600Mpa and thickness ranging from 0.12-0.5mm.

Corrugated panel roll forming machine is used to produce sinusoidal wave shape panels. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

We make different solutions according to customers’ drawing, tolerance and budget

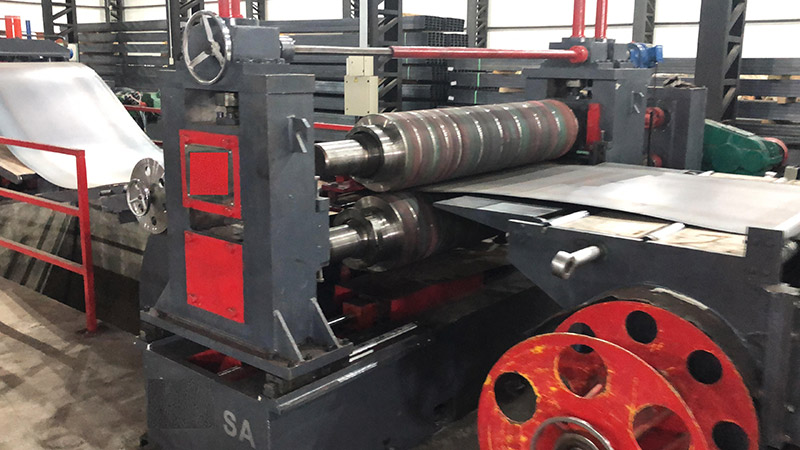

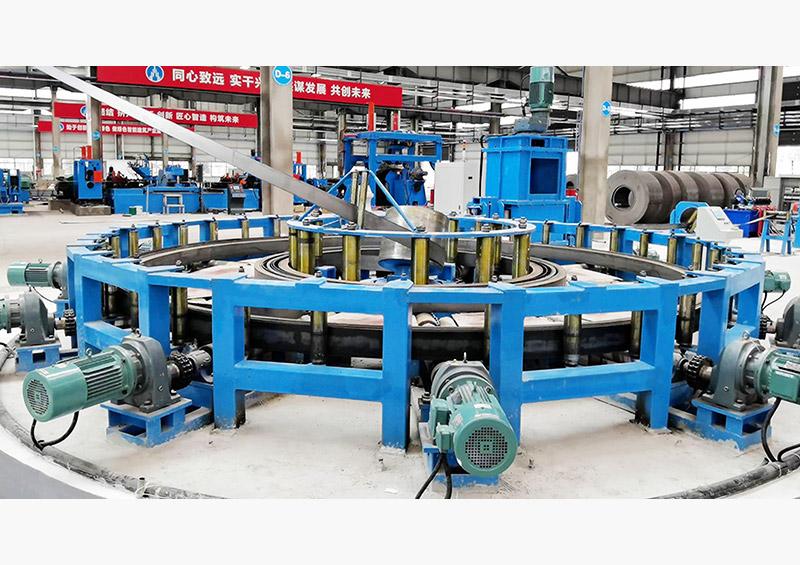

Slitting Line

Our Slitting lines are adaptable to process cold-rolled and galvanized coils, silicon steel coils, stainless coils, pre-painted coils, aluminum coils, and all sorts of plate and coated coils as well as Hot Rolled Steel Coils. And it is widely applied to many industries like automobiles, containers, household appliances, food packing, construction material etc.

We have different specifications of our slitting lines according to slitting capacities such as:

0.30 – 3 mm x 1500 mm

0.30 – 2 mm x 1250 mm

3.00 – 12 mm / 4-16 mm / 5-20 mm x 500-800 mm, 800-2000 mm, 1000-2200 mm

Auto Size Changeable C Z Purlin Roll Forming Machine

This auto size changeable C Z purlin roll forming machine is used to produce C&Z shape purlins from 100-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

This Auto Size Changeable C Z Purlin Roll Forming Machine is used to produce C&Z shape purlins from 100-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

Roof Tile Roll Forming Machine

Roof tile roll forming machine is used to roll form metal roofing step tiles which are widely used in civilian construction, such as plants, hangar, gymnasium, exhibition hall and theaters. The product of this roll forming machine features novel appearance, level surface, uniform ripple, high usage and autoimmunization, low cost and durability.

Tile & roof panel double layer machine can produce Tile sheet and roof sheet according to the client’s profile drawings and requirements. The steel trapezoidal sheets are new building materials with various thickness and colors.

Hydraulic Press Brake and Hydraulic Shearing Machine

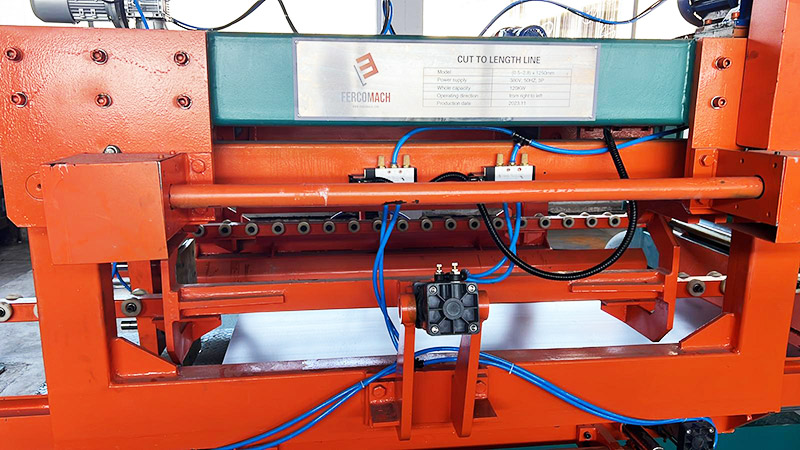

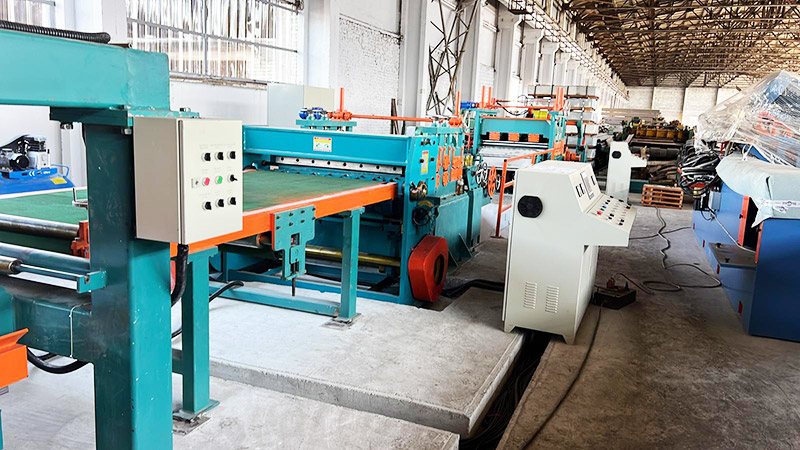

Cut to Length Line

The thin sheet cut to length line is a kind of thin coil cut to length system, used to cut cold-rolled steel, coil plates, stainless steels, galvanized steel plate color, etc into length-gauged plates. Strip thickness: 0.3~3mm or (0.5~3) mm; strip width: 300~1600mm or 300~1800mm.

Thick plate cut-to-length line can meet customer’s request of max line speed 20m/min by uncoiling and leveling a coil strip, and then shearing the leveled flat strip to certain length of sheets.The thick plate cut-to-length line (plate CTL line machine) fit steel coils with thickness: (3~12mm, 4~16mm, 5-20mm) and changeable width, and length of finished sheets depend on customer’s practical need.

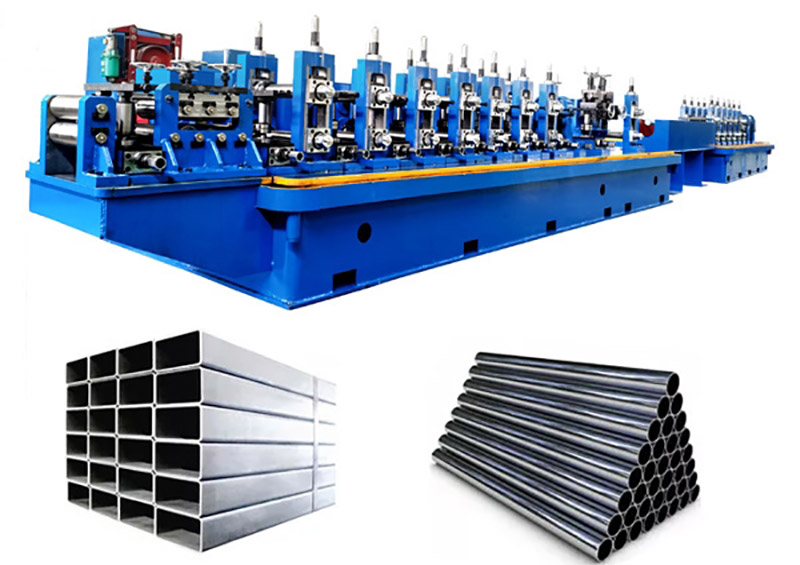

ERW Tube Machine

ERW 114 high frequency longitudinal welded pipe production line tube mill is designed to produce welded pipes of 40mm-114mm in OD and 1.0mm-3.5mm in wall thickness, as well as corresponding square and rectangular pipe.

ERW 89 high frequency longitudinal welded pipe production line tube mill is designed to produce welded pipes of 25mm-95mm in OD and 1.0mm-3.0mm in wall thickness, as well as corresponding square and rectangular pipe.

ERW 76 high frequency longitudinal welded pipe production line tube mill is designed to produce welded pipes of 12.7mm-76mm in OD and 0.7mm-3.0mm in wall thickness, as well as

corresponding square and rectangular pipe.

DC60 – Pipe Bender

With our pipe bending machine you can bend tubes or pipes up to Ø 60mm x 4mm (60mm diameter and 4mm thickness) without physical effort. With the interchangeable roll you can use a single machine for various sizes of corners, U-bends and curves for your tubes and pipes.

DC76 – Pipe Bender

With our pipe bending machine you can bend tubes or pipes up to Ø 76mm x 3mm (76mm diameter and 3mm thickness) without physical effort. With the interchangeable roll you can use a single machine for various sizes of corners, U-bends and curves for your tubes and pipes.

DM35 – Multipurpose Bender 35

DMH50 – Mechanical Multipurpose Bender

With our Mechanical Multipurpose Bending machine you can bend profiles, pipes or plates with less effort than before. The DMH machine has a hydraulically adjustable roll to achieve the curvature you like best without physical effort. Accepted dimensions: Steel Sheets (Folded on the thin side): 60×10 and 40×10. Steel Sheets (Folded on the wide side): 60×10 and 40×10. Steel Bars (square base): 35×35 and 20×20. T-type profiles: 60×7 and 30×4. UPN type profiles: UPN 80 and UPN 30.

THA60 – Hydraulic Steel Worker

taılored projects for your Needs

We can produce the machinery you need in your production line with tailor-made solutions in the technical specifications you desire.